Residential Commercial Ultra-low pressure membrane element Extremely low pressure series High-desalination membrane element High flux brackish Series Oxidation Resistance brackish series Fouling Resistance membrane element High desalination of seawater membrane element High flux membrane desalination membrane element

Internal pressure Tubular Membrane Submerged Column-Type Submerged MBR Horizontal UF Membrane External pressure

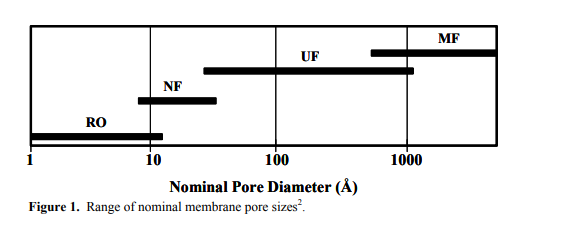

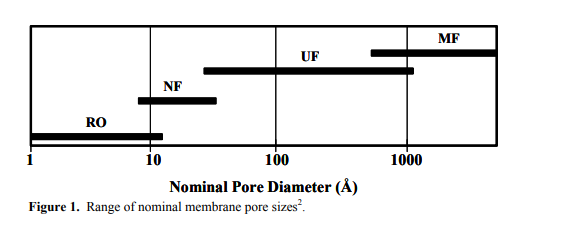

Types of membranes. Water treatment processes employ several types of membranes1 . They include microfiltration (MF), ultrafiltration (UF), reverse osmosis (RO), and nanofiltration (NF) membranes . MF membranes have the largest pore size and typically reject large particles and various microorganisms. UF membranes have smaller pores than MF membranes and, therefore, in addition to large particles and microorganisms, they can reject bacteria and soluble macromolecules such as proteins. s are effectively non-porous and, therefore, exclude particles and even many low molar mass species such as salt ions, organics, etc.s are relatively new and are sometimes called “loose”RO membranes.They are porous membranes, but since the pores are on the order of ten angstroms or less, they exhibit performance between that of RO andUF membranes.

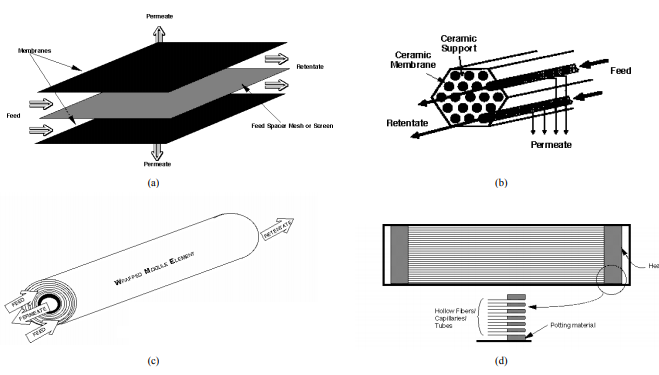

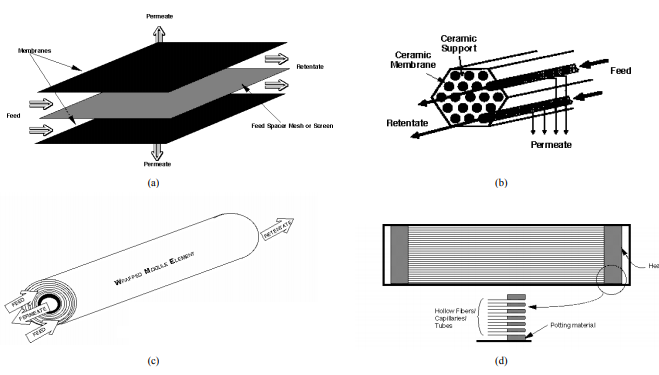

Membrane Modules. There are four main types of modules: plate-and-frame, tubular, spiral wound, and hollow fiber . The plate-and-frame module is the simplest configuration, consisting of two end plates, the flat sheet membrane, and spacers. In tubular modules, the membrane is often on the inside of a tube, and the feed solution is pumped through the tube. The most popular module in industry for nanofiltration or reverse osmosis membranes is the spiral wound module. This module has a flat sheet membrane wrapped around a perforated permeate collection tube . The feed flows on one side of the membrane. other side of the membrane and spirals in towards the center collection tube. Hollow fiber modules used for seawater desalination consist of bundles of hollow fibers in a pressure vesse. They can have a shell-side feed configuration where the feed passes along the outside of the fibers and exits the fiber ends. Hollow fiber modules can also be used in a boreside feed configuration where the feed is circulated through the fibers . Hollow fibers employed for waste water treatment and in membrane bioreactors are not always used in pressure vessels. Bundles of fibers can be suspended in the feed solution, and the permeate is collected from one end of the fibers

Types of membranes. Water treatment processes employ several types of membranes1 . They include microfiltration (MF), ultrafiltration (UF), reverse osmosis (RO), and nanofiltration (NF) membranes . MF membranes have the largest pore size and typically reject large particles and various microorganisms. UF membranes have smaller pores than MF membranes and, therefore, in addition to large particles and microorganisms, they can reject bacteria and soluble macromolecules such as proteins. s are effectively non-porous and, therefore, exclude particles and even many low molar mass species such as salt ions, organics, etc.s are relatively new and are sometimes called “loose”RO membranes.They are porous membranes, but since the pores are on the order of ten angstroms or less, they exhibit performance between that of RO andUF membranes.

Membrane Modules. There are four main types of modules: plate-and-frame, tubular, spiral wound, and hollow fiber . The plate-and-frame module is the simplest configuration, consisting of two end plates, the flat sheet membrane, and spacers. In tubular modules, the membrane is often on the inside of a tube, and the feed solution is pumped through the tube. The most popular module in industry for nanofiltration or reverse osmosis membranes is the spiral wound module. This module has a flat sheet membrane wrapped around a perforated permeate collection tube . The feed flows on one side of the membrane. other side of the membrane and spirals in towards the center collection tube. Hollow fiber modules used for seawater desalination consist of bundles of hollow fibers in a pressure vesse. They can have a shell-side feed configuration where the feed passes along the outside of the fibers and exits the fiber ends. Hollow fiber modules can also be used in a boreside feed configuration where the feed is circulated through the fibers . Hollow fibers employed for waste water treatment and in membrane bioreactors are not always used in pressure vessels. Bundles of fibers can be suspended in the feed solution, and the permeate is collected from one end of the fibers